Solemaker

2016-2018

with Loe Feijs, Admar Schoonen, Bart Pruijmboom, Eva Klabalova, Henry Lin, Erwin Hoogerwoord, Fiore Basile, Rueben Lekkerkerker, Nik van Sleeuen, Sigridur Helga Hauksdottir, and Maximillian Morres

Math Data & Computing, Technology & Making, Wearer & Society, Social & Communication, Design & Research Process

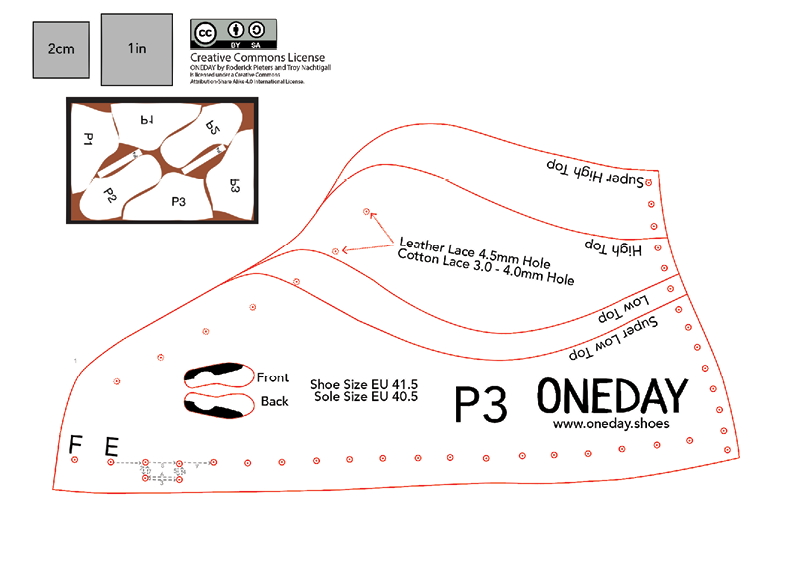

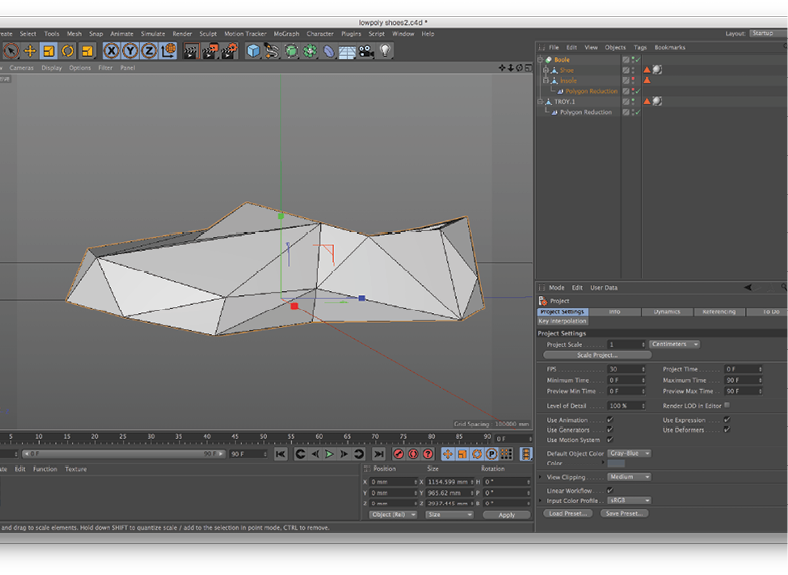

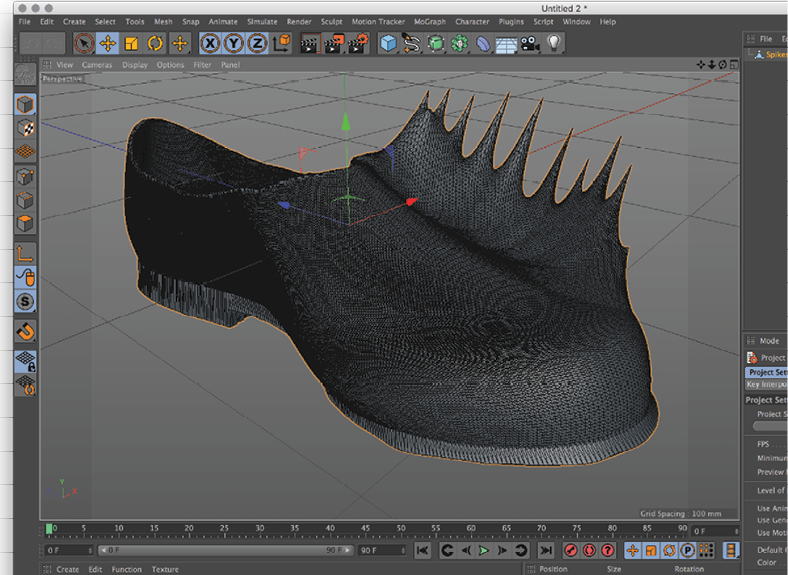

Over many years and with several stakeholders, a software product service system was created to make shoes with user data. In an artisan shoe system, the shoemaker constructs a sole from a base pattern piece or patterns specifically drafted to the wearer's foot. Industrial shoe making starts with a last in a size EU39. CAD/CAM software or manual methods are used to model the sole from a shoe last. All other sizes are graded from the median EU39. In Solemaker.pde the shape of the individual foot is entered into the UI. The tread pattern is created by a stakeholder with the help of templates as needed. The sole is then generated to .gcode and printed using a Prusa or Ultimaker compatible printer.

Solemaker.pde was designed to explore manufacturing and materialization in a UPPS system. Solemaker.pde was created to prove that mathematical formulas could generate gCode. gCode was to be generated and tested on different FDM 3D printers capable of printing in flexible filaments. The project aimed to allow shoes to be manufactured anywhere. Instead of injection molding, a person could print the sole themselves, or send it to a print service. Key to this process was understanding how to do distributed production. Solemaker.pde gave control over the gCode generation (slicer) process to be able to program not only the form but also the behavior of the material. This work was published at ISWC 2017 (Design Exhibition Award), RTD 2019 and CHI 2019. It has been featured in many exhibitions.