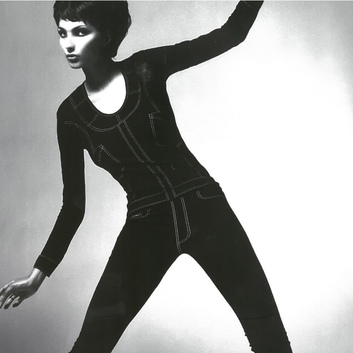

Seamless Jean Jeggings

2005

with Emilio Cavallini, 'Bepe'

Social & Communication, Creativity & Aesthetics, Design & Research Process, Business and Entrepreneurship

Working with Emilio was always an adventure. One of the unique aspects of seamless knitwear is its ability to deform and stretch on the knitting machine and on the body. There is a distortion field that occurs when the body meets a seamless knitted garment that can be controlled via a series of specialized knitting stitches.

With the seamless jeans series we explored how to use this knitting technology to reduce the amount of material/number of processes needed while creating a product that could work for at least 95% of our users. We had to create more dynamic 3D knits where the textile density was changed to create better fitting garments as we looked to fit of the user. These had to change with different body shapes.

We chose jeans not only because of the desire for skin tight jeans in fashion at that moment but also because a stretch cotton yarn capable of passing through a Santoni knitting machine had just been invented. Innovation takes effort, but after six months of 12 hour days we managed to create a thick jeans like material on tubular knitting machine.

The amazing part of the project was the fact that only two models need produced (S/M, M/L) to fit the majority of users as the knit would adapt on body. This was thanks to a loosening and straightening of specific yarns in specific places to cause the knit to adaptively fit to the wearer. This project required that I learn textile design on the job via experimentation. In no other project have I ever used as much calculus in order to calculate slope plane. This project launched what would become known as jeggings in fashion. Sales reached 500,000 EUR.